BEWARE!!: Many of the Sport Court companies subcontract their resurfacing work.

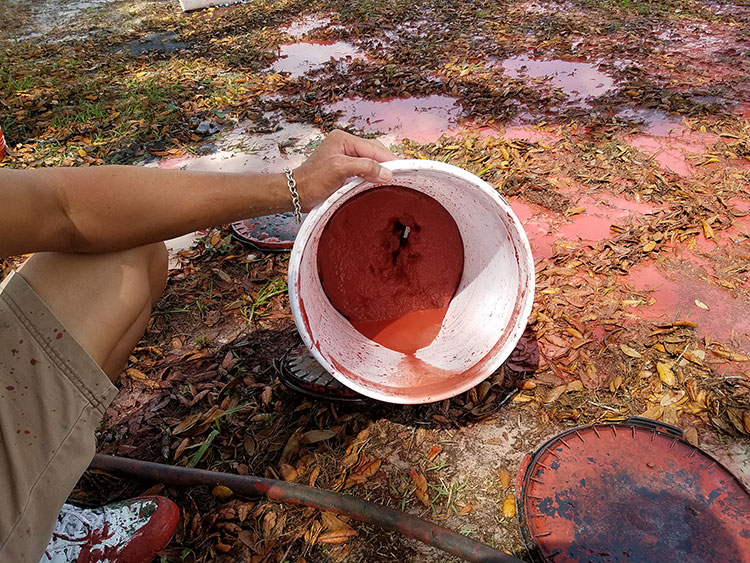

Furthermore, they use the same lower quality, concentrated form of material for both Acrylic Surfacer and Color. This material is mixed with sand and tinted at the jobsite and will not yield as durable solution as when using “factory blended” color systems. The color will chalk out prematurely due to lesser quality materials, poor quality mixing techniques and the amount of UV light and rain in the Florida climate.

J’s Quality Courts’ Difference

If the goal for your court is to have the longest lasting vibrant color surface, then you need to pay attention to what materials are being used. Most contractor’s bids will look very similar and include 1-2 coats of Acrylic Resurfacer (AR), 2 + coats of color and line striping. THIS CAN BE VERY DECEIVING ON HOW THE MATERIALS ARE DELIVERED, MIXED AND THE DURABILITY OF THE SYSTEM!

1. ACRYLIC RESURFACER (AR) recommended for asphalt surfaces

Is an acrylic emulsion, typically tinted black at the factory that is designed to fill minor depressions and voids found on an asphalt surface. It is very sticky and its main functions are to level and smooth the surface providing an underlayment that will improve the bond between the old playing surface and new color layers. Sand is typically blended into AR at the jobsite to fill appropriately and create the appropriate surface texture. A well maintained court will require only one layer of AR. We typically only use multiple coats of AR on new asphalt courts or severely worn hard courts that have extensive damage.

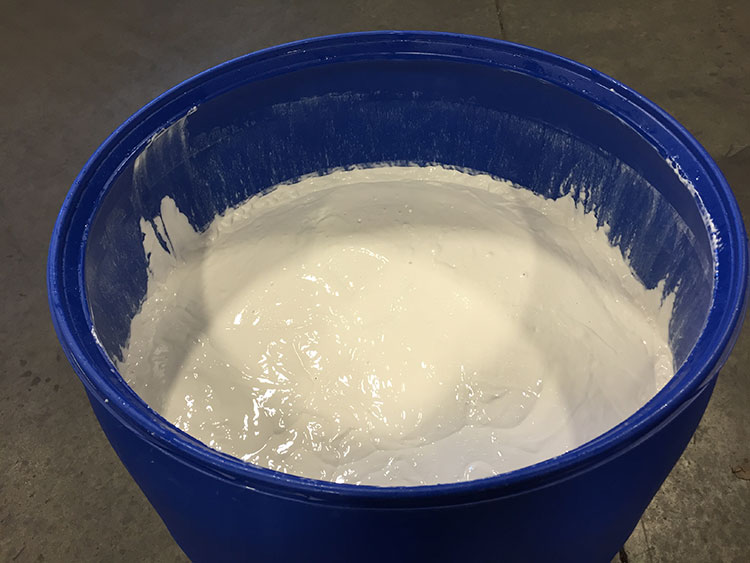

WARNING: “NEUTRAL” COLORED ASPHALT RESURFACER SHOULD NEVER BE ALLOWED TO BE TINTED AND MIXED AT THE JOBSITE TO BE USED AS THE COLOR LAYERS J’S Quality Courts: Novasurface AR is BLENDED AT THE FACTORY IN LARGE BATCHES with proprietary fillers and two high solid black pigments that can only be properly dispersed with high speed mixing blades. Impossible to replicate this on the job site

2. ACRYLIC COLOR (minimum 2 layers)

Is a sand filled, non-slip 100% acrylic all-weather emulsion designed for color-coating tennis, basketball and multi-sport recreational surfaces constructed with concrete and asphalt pavements. Fine silica sands and fillers are blended into the material to create playability factors while reducing streaking or highlighting of the surface material.

WARNING: Many contractors will use ‘Neutral” AR and tint for both AR and color layers or they buy concentrated form of color material and mix sand and tint at the jobsite. The resulting material will be less consistent, durable and chalk out prematurely because it is a lower quality mixing method for the material. J’s Quality Courts: Nova’s Combination Surface contains proprietary fillers, rounded aggregate and high solids pigments that are blended AT THE FACTORY IN LARGE BATCHES with high speed mixing blades providing greater consistency and dry film thickness. Each factory supplied system has undergone 2X the ASTM standard for durability and color retention. It is impossible to replicate this when tinting and mixing at the jobsite.

3. LINE PAINTING

Consists of a primer coat applied over masking tape followed by the application textured line paint coat(s). The primer is a clear 100% emulsion that ensures crisp clean lines by sealing the voids between the masking tape and the court. The line paint is specially formulated and blended with silica sand and fillers to match the texture of the surrounding court area yielding a consistent bounce.

Warning: Cheap tape, watered down primer and paint will yield “sloppy” inconsistent lines J’s Quality Courts: High quality tape, Nova’s Seal-a-line primer and Novatex paint provide the most “crisp” and consistent lines typically with one coat.